How Do You Find Diameter Of A Cylinder

Kalali

Mar 15, 2025 · 6 min read

Table of Contents

How Do You Find the Diameter of a Cylinder? A Comprehensive Guide

Determining the diameter of a cylinder is a fundamental task in various fields, from engineering and manufacturing to scientific research and everyday problem-solving. Understanding the different methods available, and choosing the right one depending on the context and available tools, is crucial for accurate measurements. This comprehensive guide explores multiple approaches to finding the diameter of a cylinder, ranging from simple direct measurements to more sophisticated techniques.

Understanding Cylinders and Their Dimensions

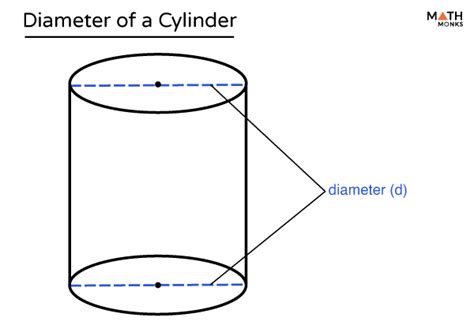

Before diving into the methods, let's briefly define key terms. A cylinder is a three-dimensional solid geometric shape with two parallel circular bases connected by a curved surface. Its key dimensions are:

- Diameter: The distance across the circle, passing through the center. This is what we'll be focusing on.

- Radius: Half of the diameter.

- Height/Length: The distance between the two circular bases.

- Circumference: The distance around the circular base.

Knowing the relationship between these dimensions is fundamental to calculating the diameter. For example, the diameter is twice the radius (Diameter = 2 * Radius), and the circumference is π (pi) times the diameter (Circumference = π * Diameter).

Methods for Determining Cylinder Diameter

The best method for finding the diameter of a cylinder depends on the size, material, accessibility, and precision required. Here's a breakdown of common techniques:

1. Direct Measurement Using Calipers

This is the most straightforward and often the most accurate method for measuring the diameter of smaller cylinders. Calipers, specifically vernier calipers or digital calipers, are precision measuring instruments designed for accurate linear measurements.

How to use calipers:

- Clean the surfaces: Ensure both the cylinder and the caliper jaws are clean and free of debris to ensure an accurate reading.

- Position the cylinder: Carefully place the cylinder between the jaws of the caliper.

- Close the jaws: Gently close the jaws until they firmly but gently contact the cylinder's opposite sides.

- Read the measurement: Record the reading displayed on the caliper. This reading directly represents the diameter.

Advantages: Direct, accurate, relatively inexpensive. Disadvantages: Not suitable for large cylinders, requires physical access to the cylinder.

2. Direct Measurement Using a Ruler

While less precise than calipers, a ruler can be a viable option for larger cylinders or when high precision isn't critical.

How to use a ruler:

- Position the ruler: Place the ruler across the cylinder's circular base, ensuring it passes through the center.

- Measure the distance: Note the distance between the two points where the ruler intersects the circumference. This gives you the diameter.

Advantages: Simple, readily available. Disadvantages: Less accurate than calipers, requires careful positioning to ensure accuracy. Error increases with the cylinder's diameter.

3. Measuring the Circumference and Calculating the Diameter

If direct measurement isn't feasible, you can measure the circumference and calculate the diameter using the formula: Diameter = Circumference / π

How to measure circumference:

- Use a flexible measuring tape: Wrap a flexible measuring tape around the cylinder's circular base.

- Record the measurement: Note the measurement indicated on the tape. This is the circumference.

- Calculate the diameter: Divide the circumference by π (approximately 3.14159).

Advantages: Useful when direct measurement is difficult. Disadvantages: The accuracy depends on the accuracy of the circumference measurement. Errors in measuring the circumference are directly reflected in the calculated diameter. Requires additional calculation steps.

4. Using a Micrometer

For extremely precise measurements, especially for smaller cylinders, a micrometer is the instrument of choice. Micrometers offer significantly higher precision than calipers.

How to use a micrometer:

- Prepare the micrometer: Ensure the micrometer is properly zeroed and calibrated.

- Position the cylinder: Place the cylinder between the anvil and spindle of the micrometer.

- Close the spindle: Gently close the spindle until it makes firm contact with the cylinder.

- Read the measurement: Record the reading from the micrometer's thimble and barrel scales.

Advantages: Extremely precise measurements. Disadvantages: Expensive, requires skill and understanding to operate correctly. Not suitable for large cylinders.

5. Optical Methods: Image Analysis and Measurement Software

For situations where physical access to the cylinder is limited or difficult, optical methods can be employed. High-resolution images of the cylinder can be captured, and specialized software can be used to analyze the image and determine the diameter.

Process:

- Image acquisition: Capture a clear and well-illuminated image of the cylinder. Ensure the image is perpendicular to the cylinder's axis.

- Image analysis software: Use image analysis software with edge detection capabilities. The software will automatically identify the cylinder's edge and measure the diameter.

Advantages: Non-destructive measurement, useful for inaccessible or delicate cylinders. Disadvantages: Requires specialized equipment and software, accuracy depends on the quality of the image and the software's accuracy.

6. Indirect Measurement Through Related Properties

In specific scenarios, the diameter might be indirectly calculated if other properties of the cylinder are known. For instance, if the volume and height of the cylinder are known, the diameter can be calculated. The formula for the volume of a cylinder is: Volume = π * (Diameter/2)² * Height. Solving this equation for the diameter gives: Diameter = √(4 * Volume / (π * Height))

Advantages: Useful when direct measurement is impossible and other relevant information is available. Disadvantages: Requires knowledge of other cylinder properties (volume and height). Accuracy depends on the accuracy of those known properties.

Choosing the Right Method

The optimal method for determining the diameter of a cylinder depends on several factors:

- Cylinder size: For small cylinders, calipers or micrometers are ideal. For large cylinders, a ruler or measuring tape might be more practical.

- Required accuracy: If high precision is needed, micrometers or optical methods should be considered. For less demanding applications, a ruler or calipers might suffice.

- Accessibility: If direct access to the cylinder is limited, optical methods or indirect calculations based on known properties might be necessary.

- Available tools and resources: The choice of method will also be influenced by the tools and resources available.

Error Minimization and Best Practices

Regardless of the chosen method, minimizing measurement errors is crucial. Here are some best practices:

- Multiple measurements: Take multiple measurements at different positions along the cylinder's circumference and average the results to reduce random errors.

- Proper calibration: Ensure your measuring instruments (calipers, micrometers, measuring tapes) are properly calibrated and in good working order.

- Clean surfaces: Clean the cylinder's surface and the measuring instrument's jaws to avoid any interference that might affect the reading.

- Careful handling: Handle the cylinder and measuring instruments with care to prevent damage and ensure accurate readings.

- Environmental factors: Consider environmental factors that might influence the measurement, such as temperature and humidity.

By following these methods and best practices, you can accurately determine the diameter of a cylinder, regardless of its size, material, or the tools available to you. Remember to choose the most appropriate method based on your specific needs and circumstances. The accuracy of your results is paramount in many applications, so careful and thoughtful measurement is essential.

Latest Posts

Latest Posts

-

What Is 26 Out Of 30 As A Percentage

Mar 17, 2025

-

How Many Feet Is 26 In

Mar 17, 2025

-

What Is 6 Out Of 20 As A Percentage

Mar 17, 2025

-

What Is Melting Point Of Glass

Mar 17, 2025

-

Cuanto Es El 30 Por Ciento De 500

Mar 17, 2025

Related Post

Thank you for visiting our website which covers about How Do You Find Diameter Of A Cylinder . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.