How To Find A Diameter Of A Cylinder

Kalali

Mar 17, 2025 · 6 min read

Table of Contents

How to Find the Diameter of a Cylinder: A Comprehensive Guide

Determining the diameter of a cylinder is a fundamental task in various fields, from engineering and manufacturing to everyday problem-solving. Whether you're dealing with a simple soda can or a complex industrial component, understanding how to accurately measure or calculate this crucial dimension is essential. This comprehensive guide will explore various methods to find the diameter of a cylinder, catering to different scenarios and levels of available information.

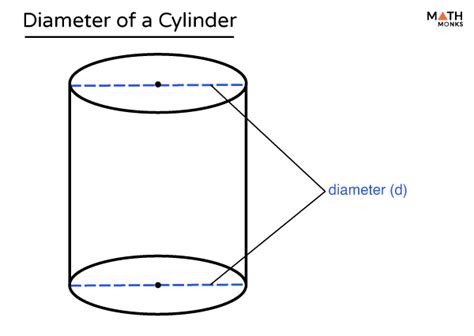

Understanding Cylindrical Geometry: Defining Diameter and Radius

Before diving into the methods, let's clarify the key terms. A cylinder is a three-dimensional solid with two parallel circular bases connected by a curved surface. The diameter is the distance across the circle through its center. The radius, on the other hand, is the distance from the center of the circle to any point on its circumference. The radius is exactly half the diameter. This simple relationship is crucial for many of the calculation methods we will explore. Understanding this fundamental relationship is the first step in accurately determining a cylinder's diameter.

Method 1: Direct Measurement with Calipers or Ruler

The most straightforward method involves direct measurement using appropriate tools.

Using Calipers: The Preferred Method

Vernier calipers and digital calipers offer the most accurate method for measuring the diameter of a cylinder. These instruments are designed to precisely measure the distance between two points, providing highly accurate readings.

-

Procedure: Carefully place the cylinder between the jaws of the caliper. Ensure the cylinder is positioned squarely to avoid inaccurate readings. Tighten the caliper jaws gently to obtain a snug fit without applying excessive pressure. Record the measurement displayed on the caliper.

-

Accuracy: Calipers generally provide measurements accurate to within a few hundredths of a millimeter or thousandths of an inch, offering high precision.

-

Advantages: High accuracy, ease of use for relatively small cylinders.

-

Disadvantages: Requires a caliper which might not always be readily available. May be less suitable for very large or irregularly shaped cylinders.

Using a Ruler: A Less Precise Approach

While a ruler offers a less accurate method compared to calipers, it can still provide a reasonable approximation, especially when high precision isn't critical.

-

Procedure: Carefully place the cylinder on a flat surface. Place the ruler across the cylinder, ensuring the ruler is perpendicular to the cylinder's axis. Read the measurement at the widest part of the cylinder. To minimize errors, take multiple readings at different points along the cylinder and average the results.

-

Accuracy: Ruler measurements are susceptible to human error and the limitations of the ruler's scale. Accuracy is generally lower than caliper measurements.

-

Advantages: Readily available and inexpensive.

-

Disadvantages: Lower accuracy compared to calipers; requires careful positioning to minimize error; prone to parallax error (error due to the angle of viewing).

Method 2: Circumference Measurement and Calculation

If direct measurement isn't feasible, you can calculate the diameter using the cylinder's circumference. This method requires measuring the circumference and then applying the formula relating circumference, diameter, and π (pi).

Measuring the Circumference

The circumference is the distance around the cylinder. You can measure it using flexible measuring tape or string.

-

Using Measuring Tape: Wrap the measuring tape snugly around the cylinder's circumference, ensuring it's parallel to the base. Read the measurement directly from the tape.

-

Using String: Wrap a piece of string around the cylinder, marking the point where the string overlaps. Then, straighten the string and measure its length using a ruler.

Calculating the Diameter from Circumference

Once you've obtained the circumference (C), you can calculate the diameter (d) using the following formula:

d = C / π

Where:

- d represents the diameter

- C represents the circumference

- π (pi) is approximately 3.14159

Remember to use consistent units throughout the calculation. If the circumference is in centimeters, the diameter will also be in centimeters. The greater the accuracy of the circumference measurement, the more accurate the calculated diameter will be.

Method 3: Using the Cylinder's Volume and Height

If you know the cylinder's volume (V) and height (h), you can indirectly calculate its diameter. The volume of a cylinder is given by:

V = πr²h

Where:

- V is the volume

- r is the radius

- h is the height

We can rearrange this formula to solve for the radius:

r = √(V / (πh))

Once you've calculated the radius, you can easily find the diameter:

d = 2r

This method is useful when direct measurement of the diameter isn't possible but the volume and height are known. The accuracy of the calculated diameter depends on the accuracy of the volume and height measurements.

Method 4: Using the Cylinder's Surface Area

Similar to using volume, if you know the cylinder's surface area (A) and height (h), you can calculate the diameter. The formula for the surface area of a cylinder is:

A = 2πr² + 2πrh

This equation involves both the radius and height. Solving directly for the radius requires solving a quadratic equation. However, if you have the total surface area and height, numerical methods or software can efficiently solve for the radius and consequently, the diameter. This method is less straightforward than others and requires either a quadratic equation solver or specialized software.

Method 5: Advanced Techniques for Irregular Cylinders

The methods described above primarily apply to perfectly cylindrical objects. However, in real-world scenarios, you may encounter cylinders with slight imperfections or irregularities.

Optical Measurement Techniques

For high-precision measurements or irregularly shaped cylinders, optical techniques such as laser scanning or structured light scanning can provide highly accurate three-dimensional models. This data can then be used to calculate the diameter at various points along the cylinder.

Image Processing and Computer Vision

Modern image processing and computer vision techniques can analyze digital images of the cylinder to determine its diameter. These techniques are often used in automated inspection systems.

Error Analysis and Minimizing Measurement Uncertainty

No matter which method you choose, it's crucial to understand and minimize potential sources of error.

-

Calibration: Ensure your measuring instruments (calipers, rulers, measuring tapes) are properly calibrated.

-

Multiple Measurements: Take multiple measurements at different points along the cylinder and average the results. This helps to reduce the impact of random errors.

-

Consistent Units: Use consistent units throughout your calculations.

-

Proper Handling: Handle the cylinder carefully to avoid deformation or damage that could affect your measurements.

-

Environmental Factors: Consider factors such as temperature and humidity, which can slightly affect the dimensions of the cylinder.

Conclusion: Choosing the Right Method

The best method for determining a cylinder's diameter depends on the specific circumstances. For high accuracy, calipers are preferred. If only the circumference is readily measurable, the calculation method is most suitable. When volume and height are known, the volume-based calculation offers an indirect approach. For irregularly shaped cylinders, advanced techniques may be necessary. Always consider the level of accuracy required and choose the method that best suits your needs and available resources. Remember to meticulously document your measurements and calculations to ensure the reproducibility and reliability of your results. By understanding these various methods and their associated limitations, you can accurately and confidently determine the diameter of any cylinder you encounter.

Latest Posts

Latest Posts

-

What Is 26 Out Of 30 As A Percentage

Mar 17, 2025

-

How Many Feet Is 26 In

Mar 17, 2025

-

What Is 6 Out Of 20 As A Percentage

Mar 17, 2025

-

What Is Melting Point Of Glass

Mar 17, 2025

-

Cuanto Es El 30 Por Ciento De 500

Mar 17, 2025

Related Post

Thank you for visiting our website which covers about How To Find A Diameter Of A Cylinder . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.