Is Ductility A Physical Or Chemical Property

Kalali

Mar 30, 2025 · 6 min read

Table of Contents

Is Ductility a Physical or Chemical Property? A Deep Dive

Ductility, the ability of a material to deform under tensile stress, is a fundamental property studied across various fields, from materials science and engineering to geology and chemistry. Understanding whether ductility is a physical or chemical property is crucial for predicting material behavior and designing effective applications. This comprehensive article will delve into the nature of ductility, explaining why it's classified as a physical property, differentiating it from chemical properties, and exploring its significance in various contexts.

Understanding Ductility: The Ability to Stretch

Ductility, simply put, is the ability of a solid material to deform under tensile stress without fracturing. This deformation is typically characterized by elongation or stretching. Think of pulling taffy—its ductility allows it to be stretched into long, thin strands. This ability is directly related to the material's atomic structure and bonding. Highly ductile materials can be drawn into wires or thin sheets without breaking. Conversely, brittle materials, like glass, lack ductility and fracture easily under tensile stress.

Measuring Ductility: Quantifying the Stretch

While we qualitatively describe materials as ductile or brittle, quantifying ductility is crucial for engineering applications. This is typically done through several mechanical tests, primarily:

-

Tensile testing: This involves applying a controlled tensile force to a specimen and measuring its elongation until fracture. The percentage elongation and reduction in area are key indicators of ductility. A higher percentage elongation indicates greater ductility.

-

Elongation at break: This represents the percentage increase in length of a specimen before fracture. It's a direct measure of how much a material can stretch before failing.

-

Reduction in area: This quantifies the decrease in cross-sectional area of a specimen during tensile testing. A larger reduction in area indicates greater ductility.

These quantitative measures allow engineers to select materials with the appropriate ductility for specific applications, ensuring structural integrity and reliability.

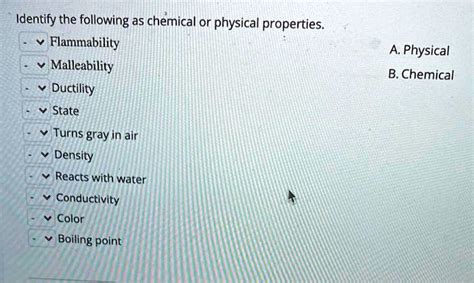

The Defining Line: Physical vs. Chemical Properties

To fully understand why ductility is classified as a physical property, we need to clearly define the distinction between physical and chemical properties:

-

Physical properties: These are characteristics that can be observed or measured without changing the chemical composition of the substance. Examples include color, density, melting point, boiling point, and ductility. These properties describe the physical state and behavior of the material.

-

Chemical properties: These describe how a substance reacts or changes its chemical composition when interacting with other substances. Examples include flammability, reactivity with acids, and oxidation. These properties involve the creation of new substances.

Ductility, in essence, is a physical property because observing or measuring it does not alter the chemical composition of the material. Stretching or deforming a metal wire, for example, doesn't change its chemical makeup; it simply changes its shape. The atoms remain the same; only their arrangement changes. This crucial distinction firmly places ductility within the realm of physical properties.

Factors Affecting Ductility: A Deeper Look into the Atomic World

The ductility of a material is profoundly influenced by several factors, all stemming from its atomic structure and bonding:

-

Crystal structure: The arrangement of atoms in a material's crystal lattice significantly affects its ductility. Face-centered cubic (FCC) metals, such as gold, copper, and aluminum, generally exhibit high ductility because their crystal structure allows for easy slip and dislocation movement under stress. Body-centered cubic (BCC) metals, like iron, tend to be less ductile at lower temperatures.

-

Grain size: Smaller grain sizes generally lead to higher strength but can sometimes reduce ductility. This is due to the increased number of grain boundaries, which can hinder dislocation movement.

-

Temperature: Temperature plays a significant role in a material's ductility. Higher temperatures often increase ductility because they enhance atomic mobility, allowing for easier deformation. This is why hot working techniques are used to shape many metals.

-

Presence of impurities and alloying elements: Impurities and alloying elements can significantly influence ductility. Some impurities can strengthen the material, reducing ductility, while others might enhance it depending on their interaction with the crystal lattice.

-

Strain rate: The speed at which stress is applied affects ductility. Higher strain rates can lead to a reduction in ductility because there's less time for atoms to rearrange and accommodate deformation.

-

Presence of defects: Defects in the crystal structure, such as dislocations, vacancies, and interstitial atoms, can affect ductility. While dislocations enable plastic deformation, excessive defect density can hinder it and make the material more brittle.

Ductility in Different Materials: A Spectrum of Behavior

Ductility isn't a binary property—it spans a wide range across different materials. Let's explore a few examples:

-

Metals: Many metals exhibit considerable ductility, making them suitable for forging, rolling, drawing, and other shaping processes. Gold, silver, and copper are exceptionally ductile metals, capable of being drawn into extremely thin wires.

-

Polymers: The ductility of polymers varies widely depending on their chemical structure and molecular weight. Some polymers are highly ductile, while others are brittle. The flexibility and elongation of many plastics are testaments to their ductility.

-

Ceramics: Ceramics are typically brittle materials with low ductility, primarily due to their strong ionic or covalent bonding. However, some advanced ceramic composites demonstrate improved ductility through specific processing techniques.

-

Semiconductors: The ductility of semiconductors also varies significantly depending on their crystal structure and dopants. Some semiconductors are relatively ductile, while others are brittle.

Understanding the ductility of different materials is essential for selecting the right material for a given application. For instance, the high ductility of copper makes it ideal for electrical wiring, while the lower ductility of iron makes it suitable for structural applications where high strength is needed.

Ductility's Importance Across Industries

Ductility is a critical property in numerous industrial applications:

-

Manufacturing: The high ductility of many metals allows for various manufacturing processes like drawing, rolling, forging, and extrusion. This allows for the creation of complex shapes and components.

-

Construction: The ductility of certain materials ensures structural integrity under stress. The ability of a material to deform before fracturing is vital for preventing catastrophic failures.

-

Automotive: Ductility is essential in the automotive industry for producing lightweight yet strong car bodies and components. This property enables crashworthiness and improved safety.

-

Aerospace: Ductile materials are used in aerospace applications to withstand extreme stress and temperature variations during flight.

-

Biomedical engineering: The ability of some biomaterials to deform under stress is critical in applications like implants and stents.

Conclusion: Ductility - A Key Physical Property

In conclusion, ductility is undeniably a physical property. It is a material characteristic that can be observed and measured without altering its chemical composition. Its ability to describe a material's ability to deform under tensile stress, without fracturing, is fundamental to material science and engineering. The wide range of ductility across various materials, from highly ductile metals to brittle ceramics, underscores its importance in diverse applications. Understanding the factors influencing ductility, and its quantification through mechanical testing, is critical for material selection, processing, and ensuring structural integrity in countless industrial applications. The continued exploration and manipulation of ductility will remain central to advancements in materials science and technological innovation.

Latest Posts

Latest Posts

-

Is The Atlantic Colder Than The Pacific

Apr 01, 2025

-

What Is The Warmest Part Of The Day

Apr 01, 2025

-

48 Oz Equals How Many Cups

Apr 01, 2025

-

What Is 8 20 As A Percentage

Apr 01, 2025

-

40 Is 80 Percent Of What Number

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about Is Ductility A Physical Or Chemical Property . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.