Spent Lead-acid Batteries Are Exempt From Hazardous Waste

Kalali

Mar 30, 2025 · 6 min read

Table of Contents

Spent Lead-Acid Batteries Are Exempt from Hazardous Waste: A Comprehensive Guide

Spent lead-acid batteries (SLABs) are a significant byproduct of various industries and applications, from automobiles to industrial equipment. However, a common misconception surrounds their classification as hazardous waste. While lead-acid batteries contain hazardous materials, under specific circumstances and regulations, they are exempt from hazardous waste classifications. Understanding these exemptions is crucial for proper handling, recycling, and environmental compliance. This comprehensive guide delves into the intricacies of SLAB exemptions, explaining the regulations, the recycling process, and the environmental benefits of responsible SLAB management.

The Hazardous Nature of Lead-Acid Batteries

Before discussing exemptions, it's essential to acknowledge the inherent hazardous nature of lead-acid batteries. These batteries contain lead, sulfuric acid, and other potentially harmful substances. Lead is a heavy metal known for its toxicity, causing neurological damage and other health problems through inhalation or ingestion. Sulfuric acid is a corrosive substance that can cause severe burns. Improper handling or disposal of SLABs can lead to soil and water contamination, posing significant environmental risks. This is why responsible management is paramount.

Why the Exemption Exists?

Despite the inherent hazards, spent lead-acid batteries often receive an exemption from hazardous waste classification due to the high rate of recycling and the established infrastructure for responsible handling. The established recycling process effectively recovers valuable materials, minimizing environmental impact and significantly reducing the need for landfilling or incineration, which are typical methods for hazardous waste disposal. This efficient recycling stream is a key factor in the exemption.

Understanding the Regulatory Framework

The regulatory landscape surrounding SLABs varies depending on location. However, many jurisdictions recognize the effectiveness of the recycling infrastructure and have implemented regulations that grant exemptions under specific conditions.

Specific Exemptions and Conditions

The precise conditions for exemption differ across regions. Generally, exemptions are granted if:

- The batteries are managed by a certified recycler: This ensures adherence to stringent environmental standards during the recycling process. Certified recyclers follow specific procedures to minimize environmental risks and maximize material recovery.

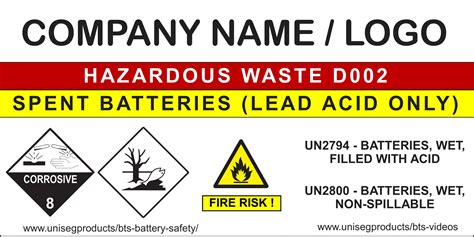

- The batteries are handled and transported according to specific guidelines: This often involves using appropriate containers, labeling, and transportation methods to prevent leaks or spills.

- The batteries are destined for recycling, not disposal: The exemption is conditional upon the actual recycling of the batteries, not simply their collection.

Failure to meet these conditions can result in the SLABs being reclassified as hazardous waste, subjecting generators and handlers to stricter regulations and potential penalties.

Regional Variations in Regulations

It’s crucial to understand that the specific rules and regulations concerning SLAB exemptions vary significantly across regions and countries. For example, the United States Environmental Protection Agency (EPA) has specific guidelines, while the European Union (EU) has its own regulations under the Waste Electrical and Electronic Equipment (WEEE) Directive. Canada, Australia, and other countries have their own regulatory frameworks. Always consult the relevant authorities in your specific region to determine the precise legal requirements for SLAB management.

The SLAB Recycling Process: A Closed-Loop System

The success of SLAB exemption programs hinges on the efficiency and effectiveness of the recycling process. This process transforms used batteries into valuable raw materials, minimizing waste and reducing environmental impact.

Stages of Recycling

The typical SLAB recycling process involves several key stages:

-

Collection and Transportation: SLABs are collected from various sources, including automotive repair shops, battery retailers, and industrial facilities. Safe transportation is crucial to prevent accidents and environmental contamination.

-

Breaking and Sorting: The batteries are broken down to separate the various components – lead, plastic, and sulfuric acid. This separation is essential for efficient material recovery.

-

Lead Recovery: Lead is the most valuable component of a lead-acid battery. It's recovered through smelting, refining, and purification processes, yielding high-quality lead suitable for use in new battery manufacturing.

-

Acid Recovery: Sulfuric acid is also recovered and reconditioned for reuse in the battery manufacturing process or other industrial applications. This reduces the need for virgin sulfuric acid production, saving energy and reducing environmental impact.

-

Plastic Recycling: The plastic casing and other components are often recycled into new plastic products, minimizing waste and contributing to a circular economy.

Environmental Benefits of Recycling

The recycling of SLABs offers numerous environmental benefits:

- Reduced Lead Pollution: Recycling prevents lead from entering the environment, protecting soil and water resources from contamination. This significantly reduces the risk of lead poisoning in humans and wildlife.

- Conservation of Resources: Recycling recovers valuable materials, reducing the demand for virgin lead and sulfuric acid, conserving natural resources.

- Energy Savings: Recycling requires less energy than producing new lead from raw materials, contributing to a reduced carbon footprint.

- Reduced Landfill Burden: Recycling diverts SLABs from landfills, reducing pressure on landfill space and minimizing the risk of environmental contamination from leachate.

Ensuring Compliance and Best Practices

To maintain the exemption and ensure responsible SLAB management, several best practices should be followed:

- Partner with Certified Recyclers: Selecting reputable and certified recyclers is crucial for ensuring compliance with regulations and environmental protection.

- Proper Labeling and Packaging: Batteries should be properly labeled and packaged for safe transportation and handling to prevent leaks or spills.

- Accurate Record Keeping: Maintaining accurate records of SLAB generation, transportation, and recycling is essential for demonstrating compliance with regulations.

- Employee Training: Training employees on proper handling, storage, and transportation of SLABs is vital for preventing accidents and ensuring safety.

- Regular Audits: Conducting regular audits to ensure compliance with regulations and best practices is a key component of a robust SLAB management program.

The Future of SLAB Management

As environmental concerns continue to grow, there is an increasing emphasis on sustainable SLAB management practices. Advancements in recycling technology are continually improving the efficiency and effectiveness of the recycling process, maximizing material recovery and minimizing environmental impact.

Furthermore, research into alternative battery technologies is ongoing, exploring more environmentally friendly battery chemistries that might reduce the reliance on lead-acid batteries in the future. However, for the foreseeable future, lead-acid batteries will remain a significant component of various applications, and efficient recycling will remain crucial for environmental protection.

Conclusion

Spent lead-acid batteries, while containing hazardous materials, benefit from exemptions from hazardous waste classification in many jurisdictions due to the high rates of recycling and the existence of established recycling infrastructure. Understanding these exemptions, along with the intricacies of SLAB recycling, is crucial for businesses and individuals alike. By adhering to regulations, partnering with certified recyclers, and implementing best practices, we can ensure responsible SLAB management, protect the environment, and contribute to a more sustainable future. Always consult local regulations to ensure compliance in your specific region.

Latest Posts

Latest Posts

-

How Long Is 10km In Miles

Apr 01, 2025

-

How Many Cups In 8 Pints

Apr 01, 2025

-

25 Is What Percent Of 50

Apr 01, 2025

-

How To Tell If Two Functions Are Inverses

Apr 01, 2025

-

How Many Liters In 11 Gallons

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about Spent Lead-acid Batteries Are Exempt From Hazardous Waste . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.