What Is The Purpose Of The Acetylene And Oxygen Regulators

Kalali

Mar 23, 2025 · 6 min read

Table of Contents

What is the Purpose of Acetylene and Oxygen Regulators?

Welding and cutting are crucial processes in various industries, from construction and manufacturing to automotive repair and metal fabrication. These processes rely heavily on the precise control of fuel gases, most notably acetylene and oxygen. While the fuel itself is essential, the safe and efficient delivery of these gases depends entirely on the proper functioning of acetylene and oxygen regulators. Understanding the purpose of these regulators is paramount for safety, efficiency, and the longevity of your equipment. This comprehensive guide delves into the critical role these regulators play in the welding and cutting process.

The Crucial Role of Gas Pressure Regulation

Acetylene and oxygen cylinders store these gases under high pressure. Directly connecting these cylinders to a welding torch would be incredibly dangerous and impractical. The high pressure would be uncontrollable, leading to potentially catastrophic explosions or uncontrolled flames. This is where the regulators step in. Their primary purpose is to reduce the high cylinder pressure to a safe and usable working pressure. This controlled pressure is vital for:

- Safety: Regulators prevent sudden surges of high-pressure gas, mitigating the risk of explosions and injuries.

- Control: They allow for precise adjustments of the gas flow rate, enabling welders to maintain a consistent flame and achieve optimal welding parameters.

- Efficiency: Consistent gas pressure ensures a stable and efficient welding or cutting process, minimizing material waste and maximizing productivity.

- Equipment Protection: Regulators protect the delicate components of welding torches and other equipment from damage caused by high-pressure gas.

Understanding the Components of Acetylene and Oxygen Regulators

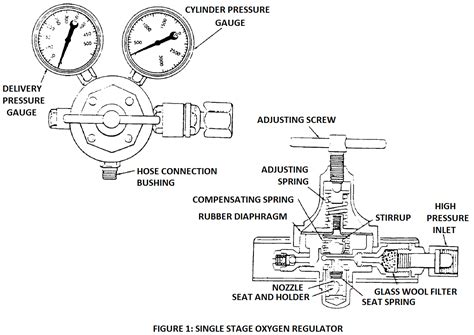

Both acetylene and oxygen regulators share a similar design, albeit with crucial differences in construction materials and pressure ranges due to the unique properties of each gas. Let's break down the key components:

1. Inlet Connection:

This is the part that connects to the cylinder valve. It’s specifically designed to fit the CGA (Compressed Gas Association) connection for the respective gas cylinder. Improper connections are extremely dangerous and should never be attempted. Always double-check the CGA connection to ensure compatibility.

2. Inlet Gauge:

This gauge displays the cylinder pressure, which remains relatively constant until the cylinder is nearly empty. Monitoring this gauge helps you track the remaining gas in the cylinder and plan for refills.

3. Pressure-Reducing Valve:

This is the heart of the regulator. It contains a diaphragm and spring assembly that mechanically reduces the high-pressure gas from the cylinder to a lower, usable working pressure. The pressure-reducing valve is precisely engineered to handle the specific characteristics of either acetylene or oxygen.

4. Adjustment Knob:

This knob allows the welder to precisely adjust the output pressure. Careful adjustment is critical for achieving the desired flame characteristics. For oxygen, the adjustment will affect the intensity and oxidizing capability of the flame. For acetylene, it impacts the fuel gas flow rate and the size and temperature of the flame.

5. Outlet Gauge:

This gauge displays the working pressure, which is the pressure at the output of the regulator. This is the pressure that is actually used by the welding torch. Maintaining the correct working pressure is key for consistent welds and cuts.

6. Outlet Connection:

This is the point where the hose connects, carrying the regulated gas to the welding torch. Similar to the inlet connection, the outlet connection needs to be correctly matched to the hose fitting.

Differences Between Acetylene and Oxygen Regulators

While both regulators share similar components, several key differences exist due to the inherent properties of acetylene and oxygen:

-

Materials: Acetylene regulators often incorporate components made of brass or other specialized materials to withstand the potential for acetylene decomposition. Oxygen regulators are typically made of materials that resist corrosion and the risk of oxygen enrichment. Mixing these regulators is extremely dangerous and strictly forbidden.

-

Pressure Ranges: Acetylene regulators handle much lower working pressures than oxygen regulators due to the inherent instability of acetylene at high pressures. Exceeding the recommended working pressure for acetylene can lead to dangerous decomposition.

-

Design Features: Acetylene regulators may incorporate additional safety features, such as a flashback arrestor, to prevent flames from traveling back into the regulator and the cylinder. Oxygen regulators focus on preventing corrosion and ensuring purity.

Safety Precautions When Using Acetylene and Oxygen Regulators

Working with acetylene and oxygen requires meticulous attention to safety. Improper use of regulators can lead to serious accidents. Here are some essential safety precautions:

- Always use the correct regulator for the specific gas. Never interchange acetylene and oxygen regulators.

- Inspect the regulators before each use. Check for any signs of damage, leaks, or corrosion. Replace damaged regulators immediately.

- Slowly open the cylinder valve. Avoid rapid opening, which can cause pressure surges.

- Always monitor the gauges. Keep track of both cylinder pressure and working pressure.

- Properly adjust the working pressure. Follow the manufacturer’s recommendations for your specific welding application.

- Never exceed the maximum working pressure. This can lead to regulator damage or even explosion.

- Close the cylinder valve before adjusting the pressure. This helps prevent unexpected gas releases.

- Turn off the regulators and release pressure before disconnecting hoses or cylinders. This prevents accidental gas leaks.

- Regularly maintain your regulators. Have them inspected and serviced by a qualified technician to ensure their continued safe operation.

Maintaining Acetylene and Oxygen Regulators

Regular maintenance is crucial for the safe and efficient operation of your regulators. While some minor maintenance can be performed by the user, more complex repairs should always be left to qualified professionals. Here's a basic maintenance checklist:

- Regularly inspect for leaks: Use soapy water to check for leaks at all connections.

- Clean the regulators: Wipe them down with a clean cloth to remove dirt and debris.

- Check the gauges: Ensure that they are accurate and functioning correctly.

- Inspect the adjustment knobs: Ensure that they operate smoothly and accurately.

- Periodic professional servicing: Have your regulators inspected and serviced by a qualified technician annually or more frequently, depending on usage intensity. This includes checking seals, diaphragms, and other internal components.

The Importance of Choosing Quality Regulators

The selection of high-quality acetylene and oxygen regulators is a critical investment in safety and productivity. Cheap, low-quality regulators may not provide the necessary precision and safety features, potentially leading to inconsistent welds, material waste, and increased safety risks. Investing in reputable brands and ensuring proper maintenance will guarantee the longevity and safety of your equipment and ultimately enhance the quality of your welding work.

Conclusion

Acetylene and oxygen regulators are indispensable components in any welding or cutting setup. Their primary purpose is to safely reduce high-pressure gases from cylinders to usable working pressures, enabling precise control of the welding or cutting process. Understanding their components, the differences between acetylene and oxygen regulators, and the essential safety precautions are crucial for every welder and metalworker. Regular maintenance and the selection of quality regulators are key investments in safety, efficiency, and the overall success of any welding or cutting operation. Prioritizing safety and investing in high-quality equipment will safeguard your work process and guarantee the longevity of your welding operations.

Latest Posts

Related Post

Thank you for visiting our website which covers about What Is The Purpose Of The Acetylene And Oxygen Regulators . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.