What Is The Difference Between A Mold And A Cast

Kalali

Apr 01, 2025 · 5 min read

Table of Contents

What's the Difference Between a Mold and a Cast? A Comprehensive Guide

Understanding the difference between a mold and a cast is crucial in various fields, from manufacturing and art to medicine and dentistry. While often used interchangeably, these terms represent distinct processes and resulting products. This comprehensive guide delves into the nuances of molds and casts, exploring their definitions, applications, materials, and the key distinctions that set them apart.

Defining Molds and Casts: The Fundamental Difference

At its core, the difference lies in their function and relationship to the final product. A mold is a container or form used to shape a liquid or pliable material, which then hardens to create a replica of the mold's shape. The mold itself is not part of the final product; it's a temporary tool. A cast, on the other hand, is the hardened material formed within the mold. It's the resulting solid object that takes on the mold's shape. Think of it like this: the mold is the template, and the cast is the resulting copy.

Mold: The Template for Creation

A mold serves as a negative impression, a hollow cavity that dictates the shape and size of the final product. Molds can be made from various materials, including:

- Metal: Metals like aluminum, steel, and bronze offer durability and precision, ideal for high-volume production and complex shapes.

- Silicone: Flexible and easily demoldable, silicone is popular for creating intricate designs and one-off pieces.

- Plaster: Economical and readily available, plaster molds are suitable for smaller projects and artistic applications.

- Wood: Often used for larger-scale projects or as a base for other mold materials, wood offers stability and ease of carving.

- Plastic: Various plastics provide versatility, ranging from inexpensive options for single use to durable materials for multiple castings.

- 3D-Printed Resins: Advanced additive manufacturing techniques allow for the creation of highly intricate and customized molds.

Cast: The Hardened Result

The cast is the positive reproduction formed within the mold. The material used for the cast depends on the desired properties of the final object:

- Metals: Casting metals like aluminum, iron, bronze, and precious metals results in strong, durable objects.

- Plastics: Thermoplastics and thermosets offer a range of properties, from flexibility to rigidity, depending on the specific polymer used.

- Resins: Epoxy resins, polyurethane resins, and other types provide versatility in color, texture, and finish.

- Concrete: Suitable for creating strong, robust objects like architectural elements or sculptures.

- Plaster: Commonly used for creating decorative items, models, and prototypes.

- Wax: Frequently employed in the lost-wax casting process for creating detailed metal castings.

Applications Across Diverse Industries

Molds and casts find extensive applications in a wide array of industries:

Manufacturing

- Automotive: Creating engine blocks, body parts, and other components.

- Aerospace: Producing intricate parts for aircraft and spacecraft.

- Electronics: Manufacturing circuit boards, housings, and other electronic components.

- Food Industry: Making chocolates, candies, and other food products.

- Plastics Manufacturing: Mass production of plastic items using injection molding.

Art and Crafts

- Sculpture: Creating bronze, plaster, resin, and other sculptures.

- Jewelry Making: Producing intricate jewelry pieces using lost-wax casting.

- Pottery: Forming ceramic pieces using molds.

- Model Making: Constructing models for architectural visualization or other purposes.

Medicine and Dentistry

- Prosthetics: Creating artificial limbs and dental implants.

- Orthopedics: Making casts for broken bones.

- Dental Work: Creating molds for dentures and crowns.

Construction

- Concrete Structures: Forming concrete walls, columns, and other structural elements.

- Bricks and Tiles: Manufacturing standardized shapes.

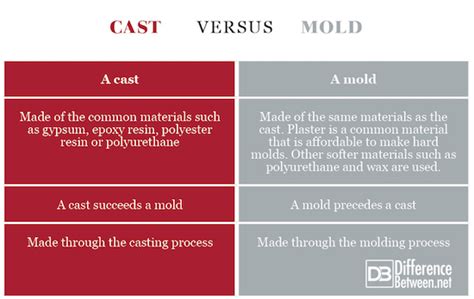

Key Differences Summarized: Mold vs. Cast

| Feature | Mold | Cast |

|---|---|---|

| Definition | Container or form for shaping | Hardened material shaped in the mold |

| Function | Template; negative impression | Resulting object; positive reproduction |

| Material | Metal, silicone, plaster, wood, plastic, 3D-printed resin | Metal, plastic, resin, concrete, plaster, wax |

| Permanence | Temporary; often reusable | Permanent; the final product |

| Shape | Negative of the final object | Positive replica of the mold |

The Lost-Wax Casting Process: A Special Case

The lost-wax casting process, also known as investment casting, exemplifies the interplay between mold and cast. In this technique, a wax model of the desired object is created. This model is then coated in a ceramic material, forming an investment mold. The wax is melted out, leaving a cavity in the mold. Molten metal is poured into this cavity, solidifying to create the final cast. The ceramic mold is then broken away, revealing the metal cast. This method allows for the creation of extremely detailed and intricate metal objects.

Advanced Molding Techniques: Pushing the Boundaries

Modern manufacturing employs sophisticated molding techniques:

- Injection Molding: High-pressure injection of molten plastic into a mold cavity.

- Blow Molding: Inflating molten plastic inside a mold to create hollow objects.

- Compression Molding: Applying pressure to mold a material between two mold halves.

- Rotational Molding: Rotating a mold containing molten plastic to distribute the material evenly.

Choosing the Right Mold and Casting Material

The selection of the mold and cast material depends heavily on several factors:

- Complexity of the design: Intricate designs might require flexible molds like silicone.

- Volume of production: High-volume production necessitates durable and reusable molds like metal.

- Material properties: The desired properties of the final cast (strength, durability, flexibility, etc.) dictate the choice of casting material.

- Budget: The cost of the mold and casting material will influence the selection.

Conclusion: Mastering the Art of Molding and Casting

The distinctions between molds and casts, while seemingly simple, underpin a vast array of manufacturing processes and artistic techniques. Understanding the nuances of each, along with the various materials and methods involved, empowers individuals and industries to create a wide range of products, from mass-produced items to unique artistic masterpieces. The constant evolution of molding and casting techniques ensures that these fundamental processes will continue to shape our world for years to come. This guide serves as a foundational resource for anyone seeking a deeper understanding of this critical area of design and manufacturing.

Latest Posts

Latest Posts

-

Cuantos Son 40 Grados Fahrenheit En Centigrados

Apr 02, 2025

-

Differentiate Between Extrusive And Intrusive Rocks

Apr 02, 2025

-

How Do You Write A Congruence Statement

Apr 02, 2025

-

What Is The Relationship Between Electron Affinity And Atomic Radius

Apr 02, 2025

-

What Is 44 50 As A Percent

Apr 02, 2025

Related Post

Thank you for visiting our website which covers about What Is The Difference Between A Mold And A Cast . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.