What Type Of Simple Machine Is A Screwdriver

Kalali

Mar 27, 2025 · 6 min read

Table of Contents

What Type of Simple Machine is a Screw Driver? A Deep Dive into Levers and Inclined Planes

The humble screwdriver. A ubiquitous tool found in every toolbox, from the most basic home repair kit to the most sophisticated engineering workshop. But have you ever stopped to consider the simple machine principles at work within its seemingly straightforward design? The answer is more complex than you might think, and understanding its mechanics reveals a fascinating interplay of fundamental physics.

The Screwdriver: A Lever and an Inclined Plane Combined

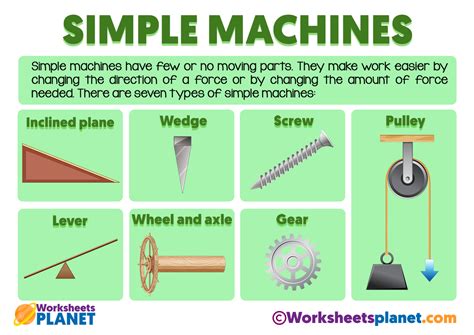

At its core, a screwdriver functions as a combination of two simple machines: a lever and an inclined plane. This dual nature allows it to efficiently transmit rotational force into a linear motion, enabling the driving or removal of screws.

The Lever in Action

The handle of the screwdriver acts as the lever arm. When you apply force to the handle, you are essentially using a lever to increase the torque (rotational force) applied to the screw head. The further away from the pivot point (the screw head) you apply the force, the greater the torque. This is why screwdrivers with longer handles are often preferred for tightening stubborn screws – they provide greater leverage. The screw head itself acts as the fulcrum, the point around which the lever rotates.

The class of lever a screwdriver represents depends on the type of screwdriver and how it is used. In most cases, a screwdriver functions as a first-class lever. The fulcrum (screw head) is located between the effort (your hand) and the load (the resistance of the screw). However, it could be argued that aspects of a second-class lever are present, specifically when significant force is applied in the vicinity of the screw. In this instance, the load (screw resistance) might be between the fulcrum and the effort. The nuances of the lever class aren't static but shift depending on the angle of application and forces at play.

Understanding Lever Mechanics:

- Effort: The force applied to the handle of the screwdriver.

- Load: The resistance of the screw to being turned.

- Fulcrum: The point of rotation – the screw head.

The effectiveness of the lever is determined by the mechanical advantage. This is the ratio of the output force (the force applied to the screw) to the input force (the force applied to the handle). A longer handle provides a greater mechanical advantage, making it easier to turn the screw.

The Inclined Plane: The Unsung Hero

The screw itself is a fascinating example of an inclined plane wrapped around a cylinder. Imagine taking a long, thin wedge (an inclined plane) and wrapping it tightly around a rod. This creates a spiral ramp. The threads of the screw act as this spiraling inclined plane. When you turn the screwdriver, you are essentially moving the screw along this inclined plane.

This inclined plane mechanism allows you to translate the rotational motion of the screwdriver into the linear motion needed to drive the screw into the material. The shallower the angle of the incline (the threads), the less force is required to turn the screw, but the screw advances slower. Conversely, steeper threads require more force, but the screw advances more rapidly. This is a key principle in choosing the right screwdriver and screw for a particular task.

Understanding the Inclined Plane Mechanics:

- Input Force: The rotational force applied by the screwdriver.

- Output Force: The linear force driving the screw into the material.

- Mechanical Advantage: The ratio of the output force to the input force, influenced by the thread pitch (steepness).

Different Types of Screwdrivers and Their Mechanics

The principles outlined above apply to various screwdriver types, though subtle variations exist:

-

Phillips Head: This cross-shaped driver head engages the screw head at four points, distributing force and reducing cam-out (the driver slipping out of the screw head). The angled faces of the screw head further contribute to the inclined plane effect.

-

Slotted Head: The simplest design, featuring a single slot. This offers a direct application of the lever principle, but is more prone to cam-out. The inclined plane effect is straightforward, relying entirely on the screw’s thread angle.

-

Torx: These six-pointed star-shaped drivers offer superior grip and reduce cam-out significantly. The lever principle remains central, while the inclined plane effect is enhanced due to the multiple points of contact with the screw head.

-

Hex (Allen) Key: Used with hexagonal-headed screws, these drivers function similarly to slotted screwdrivers. The lever action is quite direct, while the inclined plane mechanism resides in the screw's thread design.

Beyond the Basics: Factors Affecting Screwdriver Performance

While the lever and inclined plane are fundamental, other factors significantly impact a screwdriver's performance:

-

Handle Material and Design: Ergonomic handles improve grip and reduce user fatigue, effectively increasing the efficiency of the lever mechanism. Materials like rubber or textured plastic enhance grip.

-

Tip Material and Durability: Stronger tip materials (like hardened steel) improve longevity and resist wear, ensuring the driver continues to effectively engage the screw.

-

Screw Head Condition: Damaged or stripped screw heads can significantly reduce the effectiveness of the leverage and inclined plane mechanisms.

-

Lubrication: Applying lubricant to the screw threads reduces friction, minimizing the effort required and increasing the efficiency of the inclined plane mechanism.

-

Angle of Application: Applying force at the optimal angle maximizes the lever’s mechanical advantage.

The Significance of Understanding Simple Machines

Understanding the simple machine principles behind a seemingly mundane tool like a screwdriver is more than just an academic exercise. This knowledge provides valuable insights into:

- Tool Selection: Knowing the mechanics allows for selecting the right tool for the job, considering factors like screw size, material, and required force.

- Problem Solving: Troubleshooting issues like stripped screws or difficulty tightening often involves applying the principles of leverage and inclined plane mechanics.

- Innovation: Understanding the limitations and potential enhancements of the existing design can lead to innovations in tool design and manufacturing.

- Appreciation of Engineering: It highlights the ingenuity of harnessing basic physics principles to create functional and efficient tools.

Conclusion: More Than Meets the Eye

The seemingly simple act of driving a screw with a screwdriver involves a complex interplay of mechanical forces. By understanding the underlying principles of levers and inclined planes, we gain a deeper appreciation for the functionality and design of this ubiquitous tool. The screwdriver is a testament to the power of simple machines and the enduring principles of physics that shape our everyday lives. Its simple design embodies a sophisticated combination of fundamental mechanical principles that have been perfected over centuries of innovation. From the smallest household repair to the largest construction project, the humble screwdriver stands as a symbol of efficient engineering based on the timeless principles of simple machines.

Latest Posts

Latest Posts

-

Which Value Is An Output Of The Function

Mar 30, 2025

-

Which Intermolecular Force Increases With Increasing Molar Mass

Mar 30, 2025

-

Cuanto Es 24 Grados Fahrenheit En Centigrados

Mar 30, 2025

-

10 5 Inches Is How Many Centimeters

Mar 30, 2025

-

Cuanto Es 117 Grados Fahrenheit En Centigrados

Mar 30, 2025

Related Post

Thank you for visiting our website which covers about What Type Of Simple Machine Is A Screwdriver . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.