Reacts To Oxygen To Produce Rust

Kalali

Mar 27, 2025 · 6 min read

Table of Contents

Reacting to Oxygen: The Science and Art of Rust Formation

Rust. The word conjures images of decaying metal, crumbling structures, and the slow, relentless march of time. But what exactly is rust, and why does it form? This comprehensive guide delves into the fascinating chemistry and physics behind rust formation, exploring the factors that influence its development and examining the various methods employed to prevent or mitigate its effects. We'll explore everything from the fundamental chemical reactions to practical applications and considerations.

Understanding the Chemistry of Rust: Oxidation and Reduction

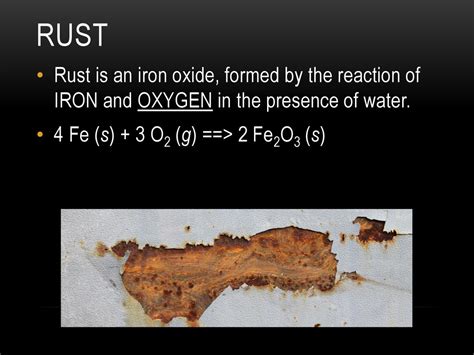

Rust, scientifically known as iron oxide, is the product of a chemical reaction called oxidation. More specifically, it's a form of corrosion, a destructive process that affects metals. This process involves the loss of electrons from iron atoms (Fe) in the presence of an oxidizing agent, most commonly oxygen (O₂), and often in the presence of water (H₂O).

The Electrochemical Process

The formation of rust isn't a simple, straightforward reaction. It's a complex electrochemical process involving two key reactions:

-

Oxidation: Iron atoms lose electrons, transforming into iron ions (Fe²⁺ or Fe³⁺). This occurs at the anodic site. The half-reaction can be represented as:

Fe → Fe²⁺ + 2e⁻

-

Reduction: Oxygen molecules gain electrons, reacting with water to form hydroxide ions (OH⁻). This happens at the cathodic site. The half-reaction is:

O₂ + 2H₂O + 4e⁻ → 4OH⁻

These two reactions are coupled, with the electrons released during oxidation flowing through the metal to the reduction site. The presence of an electrolyte, such as water containing dissolved salts, significantly speeds up this process by facilitating the movement of ions and electrons.

The Formation of Iron Oxides

The iron ions (Fe²⁺ and Fe³⁺) formed during oxidation react with hydroxide ions (OH⁻) to produce various iron oxides and hydroxides, the most common being:

- Iron(II) hydroxide (Fe(OH)₂): This is an initial product that is often unstable and rapidly oxidizes further.

- Iron(III) hydroxide (Fe(OH)₃): This is also an intermediate product that readily dehydrates.

- Iron(III) oxide (Fe₂O₃): This is the primary component of rust, often appearing as a reddish-brown flaky material. It's also known as hematite.

- Iron(II,III) oxide (Fe₃O₄): This is another common form of iron oxide, also known as magnetite, often appearing as a black or dark grey substance.

The exact composition and appearance of rust depend on several factors, including the environmental conditions, the type of iron, and the presence of other substances.

Factors Influencing Rust Formation: A Multifaceted Process

Numerous factors influence the rate and extent of rust formation. Understanding these factors is crucial for developing effective rust prevention strategies.

Oxygen Availability

Oxygen is the primary oxidizing agent in the rusting process. The higher the concentration of oxygen in the surrounding environment, the faster the rust will form. This explains why rusting is accelerated in humid and wet environments compared to dry environments.

Water Presence

Water acts as an electrolyte, facilitating the movement of ions and electrons between the anodic and cathodic sites. Without water, the electrochemical process is significantly slowed down. However, even a thin film of moisture can be sufficient to initiate rusting. The presence of dissolved salts in the water (like seawater) dramatically accelerates rust formation due to increased conductivity.

pH Level

The acidity or alkalinity of the environment can significantly impact rust formation. Acidic conditions generally accelerate rusting, while alkaline conditions can inhibit it. This is why many rust prevention treatments involve the application of alkaline substances.

Temperature

Higher temperatures generally accelerate chemical reactions, including the rusting process. The increased kinetic energy at higher temperatures leads to more frequent collisions between atoms and molecules, increasing the rate of oxidation.

Presence of Other Ions

The presence of other ions in the environment can also influence rusting. For example, chloride ions (Cl⁻), often found in seawater and de-icing salts, can accelerate the process by breaking down the passive oxide layer that naturally forms on iron surfaces and promoting pitting corrosion.

Type of Iron

The type of iron used also plays a role. Different alloys of iron, such as stainless steel, exhibit different levels of resistance to rust due to their composition. The addition of elements like chromium and nickel significantly enhances corrosion resistance.

Preventing Rust: A Multi-pronged Approach

Preventing rust formation is essential for protecting metal structures and preserving their integrity. A variety of methods are employed, either individually or in combination, to achieve this goal.

Protective Coatings

Applying protective coatings is one of the most common and effective ways to prevent rust. These coatings act as a barrier, preventing oxygen and water from reaching the iron surface. Examples include:

- Paints: A wide variety of paints, including oil-based, acrylic, and epoxy paints, can provide effective protection against rust.

- Coatings: Specialized coatings, such as zinc (galvanization), aluminum, or other metal coatings, offer excellent protection through sacrificial protection or barrier protection.

- Plastics: Plastic coatings can also offer protection against rust, especially in harsh environments.

Cathodic Protection

This method utilizes an electrochemical process to prevent rusting. A more reactive metal, such as zinc or magnesium, is connected to the iron structure. The more reactive metal acts as an anode, sacrificing itself to protect the iron cathode. This is commonly used for underground pipelines and other large structures.

Inhibitors

Chemical inhibitors can be added to the environment to slow down the rusting process. These inhibitors often react with oxygen or interfere with the electrochemical reactions involved in rust formation.

Alloying

Modifying the iron composition by adding other elements, such as chromium and nickel, can produce alloys (like stainless steel) that are much more resistant to rust. These elements help to form a passive oxide layer that protects the underlying metal.

The Impact of Rust: Consequences and Considerations

Rust is more than just an aesthetic issue; it has significant practical implications:

- Structural damage: Rust weakens metal structures, potentially leading to failure and catastrophic consequences in bridges, buildings, and vehicles.

- Economic losses: The cost of rust-related damage and maintenance is enormous, affecting various industries and infrastructures globally.

- Environmental concerns: The production and disposal of materials used to combat rust contribute to environmental impacts.

- Safety hazards: Rusted components in machinery and equipment can create safety hazards, leading to accidents and injuries.

Conclusion: A Continuous Battle Against Oxidation

Rust formation is a complex interplay of chemical and environmental factors. Understanding these factors is critical for developing effective strategies for rust prevention and mitigation. From protective coatings and cathodic protection to alloying and the use of chemical inhibitors, a multifaceted approach is necessary to combat the ever-present threat of rust and protect our metal structures and resources. Continuous research and development are essential to improve our ability to prevent rust and minimize its detrimental effects on our infrastructure and environment. The battle against oxidation is a continuous one, requiring vigilance, innovation, and a deep understanding of the scientific principles involved.

Latest Posts

Latest Posts

-

How Does A Sedimentary Rock Become An Igneous Rock

Mar 30, 2025

-

What Is A Positive Ion Called

Mar 30, 2025

-

How Many Liters In 64 Oz

Mar 30, 2025

-

What Does Mu Mean In Statistics

Mar 30, 2025

-

What Type Of Organism Is The Grass

Mar 30, 2025

Related Post

Thank you for visiting our website which covers about Reacts To Oxygen To Produce Rust . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.